Search This Supplers Products:Rubber sheetsilicone sheetsrubber matrubber floorpvc sheethorse stall mats

Precautions for the use of oil-resistant rubber sheets

time2020/05/29

- Precautions for the use of oil-resistant rubber sheets

Precautions for the use of oil-resistant rubber sheets

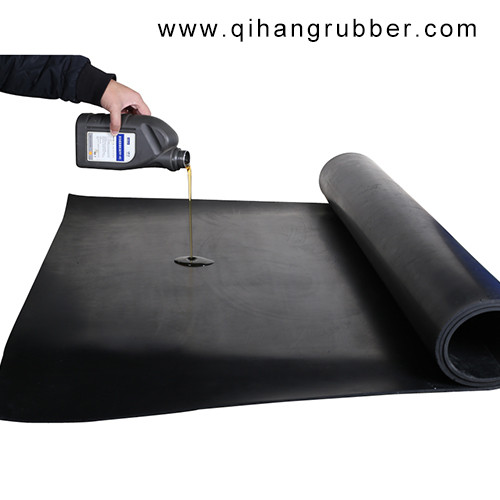

1. If the oil-resistant rubber sheet is in contact with an oil medium for a long time during use, the oil can penetrate into the rubber to cause swelling, which reduces the strength and other mechanical properties of the rubber. Oil can swell the rubber because the oil penetrates into the rubber, and the molecules diffuse to each other, which changes the network structure of the vulcanized rubber.

2. The oil resistance of the oil-resistant rubber sheet depends on the polarity of the rubber and oil. The rubber molecules contain polar groups, such as cyano, ester, hydroxyl, and chlorine atoms, which cause the rubber to show polarity. When the polar rubber is in contact with non-polar petroleum oils, the polarities of the two are quite different. At this time, the rubber is not easy to swell.

3. One of the main uses of oil-resistant rubber sheet is as a movable seal. Due to the high rotation speed of the rotating shaft, the sealed products must bear a large friction torque, especially in the case of poor lubrication, the heat generated in the sealed area is large, which will cause the rubber to be sticky or improve the adhesion with the metal. The seal is destroyed, which in turn causes the seal to fail.

4. One of the more effective ways to reduce the temperature in the friction area is to add lubricating fillers to the rubber to reduce the friction factor of the rubber. Such as molybdenum disulfide and graphite added to the rubber production formula. In addition, the use of polytetrafluoroethylene, PTFE has excellent resistance to media and atmospheric aging, a wide range of use, has good self-lubricating properties, the friction factor is very small, covering it on the rubber surface can be greatly reduced The surface friction factor of rubber products improves wear resistance and medium resistance.