Search This Supplers Products:Rubber sheetsilicone sheetsrubber matrubber floorpvc sheethorse stall mats

Rubber sheet characteristics knowledge point

time2020/10/22

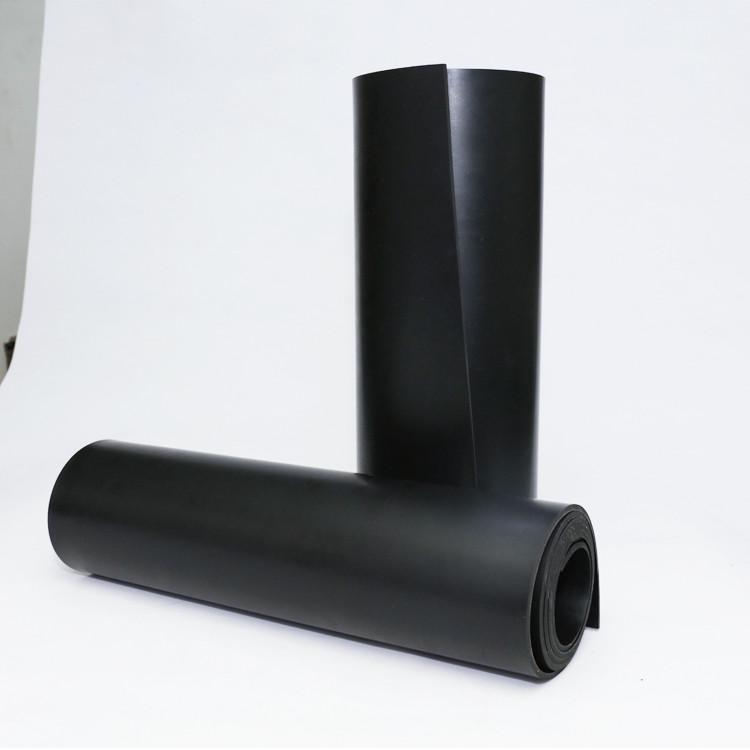

- Rubber sheet characteristics

rubber sheet for gasket

Rubber sheets are available in various lengths and widths. These sheets are cut according to customer requirements. Various types of rubber are used to make sheets. These sheets are very popular and used in an extensive range applications. There are a comprehensive range of rubber sheets for general, industrial and mining applications. These sheets are also available in vulcanized black as well as colored sheets for technical uses and industrial applications. There can also be smooth surfaced rubber sheets or with a canvas-type print on one or both sides of the rubber sheets. These sheets insertions are usually designed for use in applications where stresses are generally static and pressures are low. There can be cloth insertion, metal mesh insertion, gauze, nylon cloth, and copper insertion.

General Characteristics of rubber sheets:

● A high performance sheet is suitable for continuous use at temperatures from -80 degree F to 425 degree F and intermittent use from -100 degree to 500 degree F, depending on media and application.

● Chemically extremely stable.

● Suitable for use with many acids and alkalis.

● No harmful toxic or physiological effects.

● Resistant to ozone, oxidation, ultraviolet light, corona discharge, cosmic radiation and weathering in general.

● Low flammability and low smoke.

Forms of rubber sheets:

● Rolls

● Tiles

● Sheets

Types of sheets:

● Neoprene : This is one of the most popular and earliest synthetic rubber, resistant to greases, inorganic chemicals and many oils. Neoprene is a good material to make sheets as it has good ageing, weathering and abrasion resistant characteristics. Neoprene rubber can be specially compounded to be flame retardant.

● Nitrile: Nitrile is another synthetic rubber used to make sheets. Many grades of this synthetic rubber are manufactured to meet various specific conditions. Nitrile is a good material to make sheets because it is resistant to oils, greases, liquid fuels and a wide range of industrial solvents. It can also be compounded to give mechanical and good abrasion resistant properties.

● Ethylene Propylene Diene Monomer (EPDM): These sheets are also made of EPDM rubber. This type of rubber is weather, ozone, steam and chemical resistant. It also has a good electrical and low permeability characteristics. EPDM sheets are being used in increasing quantities by the engineering industry.

● Butyl: Butyl sheets are available in various widths and thickness. It can be fabricated to the required size using uncured butyl tape and a special heat bonding process.

● Viton: This is a very high grade synthetic rubber used to make sheets for the most demanding applications. It has excellent resistance to oxygen, ozone and natural weathering. It is ideal to make sheets because it is resistant to many of the more pernicious chemicals and solvents. This rubber is mainly used for hydrocarbons and oxidizing acids at high temperatures. Viton sheets are also flame resistant with the exceptional heat resistance.

● Silicone: A very popular type of synthetic rubber used to make sheets is silicone. This rubber is a heat resistant synthetic and suitable for temperatures ranging from -100°C to +200°c and above. It has inherent non-stick properties and also has good dielectric properties. Most grades are odorless and tasteless. Tensile properties are not high and silicone rubber has poor abrasion resistance but still ideal for rubber sheets.